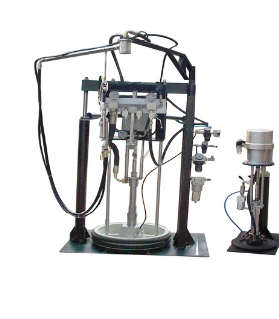

如何使用点胶机做好点胶工作?

如何使用点胶机进行点胶工作

How to use dispensing machine for dispensing

1、固化要素:关于胶水的固化,一般厂家都给出了温度曲线。一般在室温下即可固化,在实际操作中应尽量选用较高的温度进行固化,使固化后的胶水达到强度和硬度要求。

1. Curing elements: for the curing of glue, the general manufacturer has given the temperature curve. Generally, it can be cured at room temperature. In actual operation, it should be cured at a higher temperature as far as possible to make the cured glue meet the requirements of strength and hardness.

2、关于胶泡的点胶机在点胶的过程中会影响产品的质量,所以在放胶前一定不要有泡。

2. The dispensing machine of the rubber bubble will affect the quality of the product during dispensing, so there must be no bubble before dispensing.

3,真空吸入阀必须安装在配药机,由于真空回吸功能是防止胶在配药机不是调剂胶还泄漏,如果安装这个工具可以合理地调整真空吸入阀,以进一步控制滴和绘画两种情况。

3. The vacuum suction valve must be installed in the dispensing machine. Since the vacuum suction function is to prevent the glue from leaking in the dispensing machine, if this tool is installed, the vacuum suction valve can be adjusted reasonably to further control the dripping and painting.

标准4、针和类别:针标准会影响在调剂的过程中胶粘剂范围和精度,当压力,喷嘴针越大,速度越大,所以要分配的基础上机器生产产品的侵入性的标准锚点胶针,针直径长度保持胶点直径的一半,效果很好。

Standard 4, needle and category: needle standard will affect the range and accuracy of adhesive in the process of dispensing. When the pressure and nozzle needle are larger, the speed is larger. Therefore, the invasive standard anchor needle of the product manufactured by the machine on the basis of distribution is required. The diameter length of the needle keeps half of the diameter of the glue point, and the effect is very good.

配药机在配药过程中的大小是由持续的时间长短决定的,越长越好。根据我们的经验,调剂量较大。这样可以保证有足够的胶水把零件粘在一起,防止形成过多的胶水废物。

The size of dispensing machine in the dispensing process is determined by the duration of time, the longer the better. According to our experience, the amount of adjustment is large. This can ensure that there is enough glue to stick the parts together to prevent the formation of excessive glue waste.

在点胶机中一般使用环氧树脂胶、速溶胶、硅胶、无氧胶、UV胶等。

In the dispensing machine, epoxy resin glue, quick sol, silica gel, anaerobic glue, UV glue, etc. are generally used.

7,侵入性压力直接影响流的速度胶水,胶水,胶水更糟的活动变得厚,它需要更大的压力,所以我们应该基于配药机在生产过程中环境温度和侵入性胶胶量的特性来调节压力,胶侵入的压力是通过其内部压力调节阀进行调理。

7. The invasive pressure directly affects the speed of flow. The worse activities of glue and glue become thicker. It needs more pressure. Therefore, we should adjust the pressure based on the characteristics of the ambient temperature and the amount of invasive glue in the production process of the dispensing machine. The pressure of glue invasion is regulated by its internal pressure regulating valve.

上一篇:打胶机如何防止胶水沉淀?

下一篇:点胶机行业的发展思路!