灌胶机不收胶老是滴胶是怎么回事?

双液浇注机不能接受胶水的根本原因是密封不到位,漏气、漏胶阀回吸不会起到任何作用,造成了不好的效果,就像上面说的滴胶一样。

The fundamental reason why the double-liquid pouring machine can not accept glue is that the seal is not in place. The air leakage and the return suction of the leak valve will not play any role, resulting in a bad effect, just like the dripping glue mentioned above.

为什么会漏水?

Why does it leak?

一方面可能是橡胶阀门结构设计不合理,橡胶阀门整体密封性能不理想。

On the one hand, it may be that the design of rubber valve structure is unreasonable, and the overall sealing performance of rubber valve is not ideal.

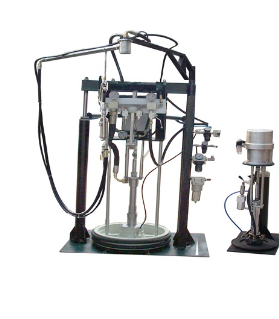

双液灌装机橡胶阀

Rubber Valve of Double-liquid Filling Machine

另一方面,橡胶阀的密封可以,但内部空间不合理,造成背压,即压力不能迅速释放,造成胶水从顶部,漏胶,胶水。

On the other hand, the sealing of rubber valves can be, but the internal space is unreasonable, resulting in back pressure, that is, pressure can not be released quickly, resulting in glue leakage from the top, glue, glue.

此外,它还可能由于使用橡胶阀门时间长,密封圈磨损,导致橡胶泄漏。

In addition, it may also lead to rubber leakage due to the use of rubber valves for a long time and the wear of sealing rings.

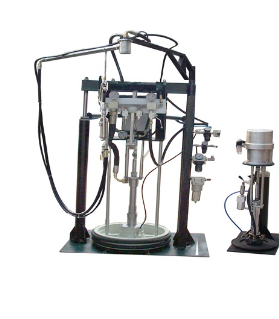

双液胶浇注机密封圈

Double-liquid glue casting sealing ring

也有可能是胶水有腐蚀性,密封圈使用的材料不耐腐蚀。

It may also be that the glue is corrosive and the material used in the sealing ring is not corrosion resistant.

双液灌装机解决了这一问题,或从结构上对橡胶阀进行了改进,使橡胶阀密封。另一方面是定期更换密封圈,用耐腐蚀密封圈。

The double liquid filling machine solves this problem, or improves the rubber valve from the structure to seal the rubber valve. On the other hand, the sealing rings should be replaced regularly and the corrosion-resistant sealing rings should be used.

If you have the requirement of Jinan two-component glue machine, you can directly click on the official website for consultation: http://www.jntiannuo.com

上一篇:打胶机的胶水在不同情况下的选择!

下一篇:中空玻璃打胶机的耗电量高不高?